HOUSE RESORT

An innovative use of bamboo and their by product has been shown for the construction of house. In the structure vide variety of structural application of bamboo (whole, split and engineered bamboo products) can be seen having architectural innovative ideas.

RURAL HOUSING

Made of cost effective local material, bamboo culms and engineered bamboo material.

Area Range : 120-180 sq ft.

Cost per sq ft : Rs.300-Rs.400

Material used : Engineered bamboo composite roofing, flooring and PCC/bamboo composite boards Cladding may be bamboo mat board.

Structure/design : Lattice/whole bamboo

Functional use : Dwelling unit

Mid Level

Primarily for urban areas where access to manufactured building components and modern practices of construction wherever substitution of building components is possible by bamboo based material it is done i.e. roofing, cladding and flooring etc.

Area Range : 48-1000 sq ft.

Cost per sq ft : Rs.300-Rs.700

Material used : Engineered bamboo composite roofing, flooring may be PCC/bamboo composite boards Cladding may be bamboo mat board.

Structure/design : Whole bamboo with engineered roofing

Functional use : Dwelling / public utility

HIGH END

Mostly public utility structures where whole bamboo used for structures highlight the aesthetics characteristics of Bamboo.

Area Range : 750-1200 sq ft.

Cost per sq ft : Rs.700-Rs.1000

Material used : whole bamboo used for structures highlight the aesthetics characteristics of Bamboo, engineered bamboo composite may also be used.

Structure/design : Whole bamboo

Functional use : Public utility

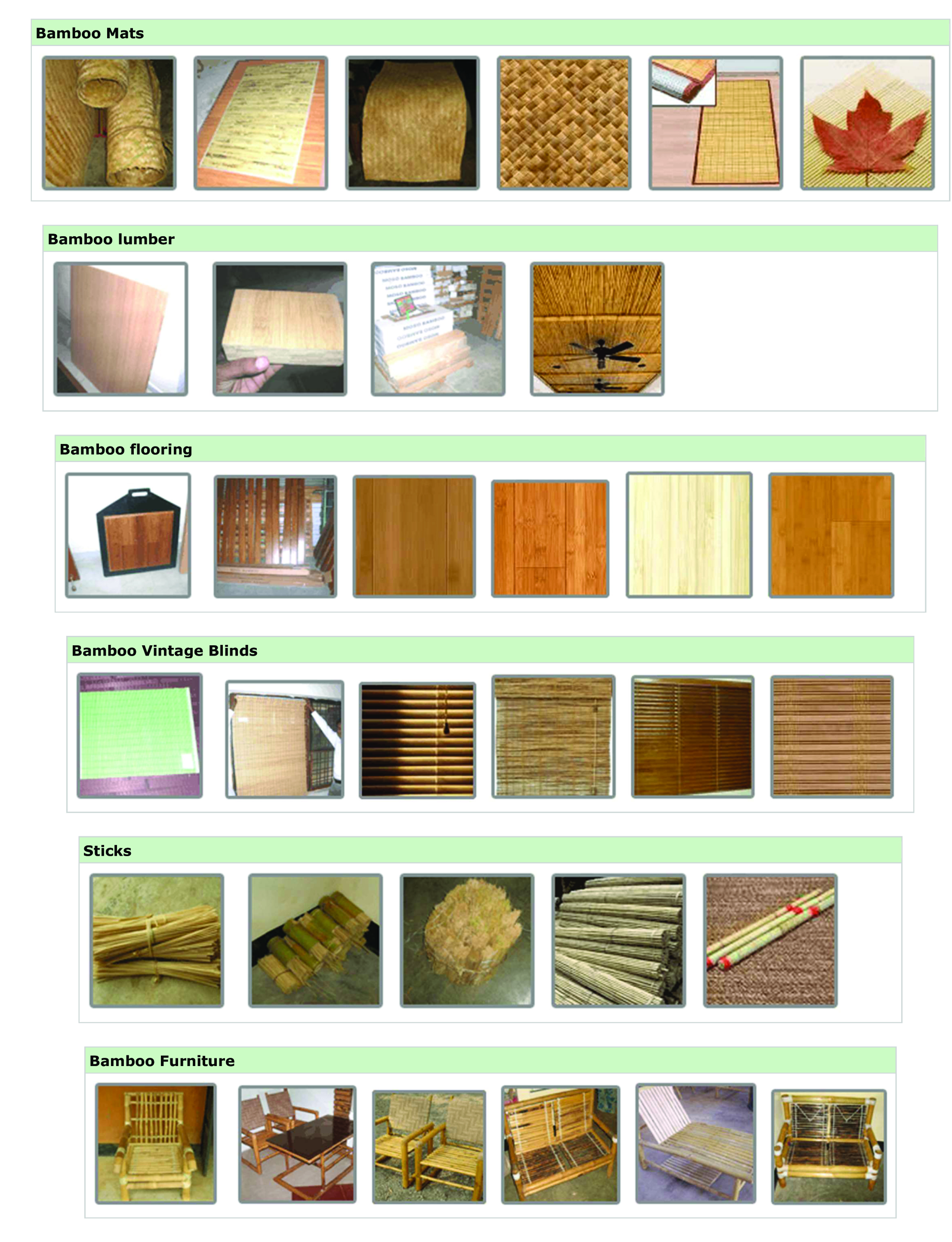

Bamboo particle boards: Bamboo particle boards, which are bamboo in combination with other cementing materials are also developed.

Bamboo Mat Board: Bamboo sliced into slivers and woven, are hot pressed to produce bamboo mat board, which is superior to plywood in strength and life period.

Timber Block / Lumber: Timbers are getting scarce day by day. Bamboo is the alternative and answer for this.

Bamboo Mat boards: Bamboo sliced into slivers and woven, are hot pressed to produce bamboo mat board, which is superior to plywood in strength and life period.

Utility Products

Bamboo has found its place in many items of daily uses which may differ from place to places.

Bamboo toothpicks: Due to its high tensile strength, bamboo is ideal for toothpick, which is used by millions of people around the globe.

Bamboo incense (agarbati) sticks: Bamboo has been extensive used for this item.

Bamboo Furniture he flexibility, strength, abundance, firmness and quick maturity of bamboo have made it very popular choice for making furniture. Today, bamboo is used in almost every type of furniture, like chairs, tables, sofas, stools, shoe racks, bookshelves, cabinets, beds, couches, recliners, etc. Indian Bamboo furniture is available in different price ranges, suiting almost every budget. The durability, low weight, easy maintenance and environmental-friendliness of the furniture further add to its charm.

Bamboo Handicrafts

There are numerous designs and varieties of handicrafts made out of bamboo. Due to its high texture, properties, high tensile strength, easy splitting possibility, and other characteristics, bamboo is a good choice of material for handicrafts.

Paper and Pulp

Main raw material for paper pulp: Bamboo has been the main material for pulp in paper industries. It is still the main material and will continue so due to its short growth cycle, large biomass production and rapid vegetative multiplication. There are two paper industries in the state which uses bamboo as one other raw material for manufactures of paper. These are JK Paper Ltd (www.jkpaper.com) Bilt (Sewa Unit), Jeypore (www.biltpaper.com)

Energy / Charcoal

The process of making bamboo charcoal is not easy and request lot of skill. Pieces of bamboo, which are taken from plants of five years old or more, are burned in an oven at a temperatures over 800 degrees centigrade. The experience, know-how, the special oven and the respect of correct temperature will allow to get very good quality bamboo charcoal after a process of 20 days long. The quality of the bamboo charcoal will be confirmed by its conductivity proving the purity of the carbon it contains.

Because of the industrialization, air pollution and water pollution are becoming serious environmental problems. Bamboo charcoal products are not only functional, but also good for protecting the environment reinforced by the fact the the plant is fertilizer and pesticide free.

The amazing properties of bamboo remain intact after any of its transformations. Bamboo charcoal can be used as is for different applications, as explained below, but can also be mixed with other components to achieve specific results.

Bamboo charcoal has high mineral contents such as potassium, calcium, iron, and sodium. And for so many years, people especially in Japan uses bamboo charcoal for many purposes, from households, kitchen tools to medicines.

Bamboo is burnt at high temperature of 800c (1,475F) or more, until it enters into the genre of the white charcoal. The calorific value reaches up to 7000 calories which is 4000 calories over normal wood charcoal. In terms of carbonization, there is much time and skill required (around 20 days) to process the bamboo to its carbonized form or charcoal structure compared to normal wood charcoal process.

it can be observed from the microstructure of bamboo charcoal under electron microscope, the main composition is carbon with 6 sided or hexagons holes joined together. This effectively becomes a very unique and natural absorption system like a hard 'sponge', which can trap impurities, harmful matters and gases.

These unique properties make bamboo charcoal good for deodorization, purification, and humidity regulator (The adsorption capacity of bamboo charcoal to methanol, benzene, methyl benzene, ammonia, and chloroform were being studied and tested in laboratories).

In addition, it is capable of protecting from electromagnetic waves, generating far infrared rays and releasing negative ions. The infrared rays emitted constantly from charcoals reduce moisture in the air into fine particles that naturally change into negative ions.

The electric conductivity of bamboo charcoal is improved by the carbonization temperature increase also influencing an effective property for electromagnetic wave shielding.

Presently, there is some on-going research in developing products with electromagnetic shielding and anti-radiation property

Fiber / Textile

Its Innovative, Its amazing, Its Cool, Its Bamboo.

What is so special about a bamboo fiber shirt?

Bamboo Shoots

A bamboo shoot is a young culm harvested at the time, or shortly after it appears above the soil surface. When the shoot pierces the ground, critical bio-chemical processes start. These lead to rapid growth, as well as concurrent hardening, as the shoot elongates and turns into a woody culm.

In Odisha the new sprouts of bamboo culms (Karadis) are procured from forests by local people to prepare pickle and food beverages. The fresh young shoots are sliced and fried to prepare the dish. It is also added to other dishes made from tomato and ladys finger to add to taste. Since the Shoots are available only during rains, the villagers convert the young shoots to small pieces like noodles, dry it and store for the rest of the year. The dried shoots are called Hendua. Hendua is added to a number of dishes prepared from vegetables and fish to have a special flavour. The demand for karadi is so much in certain parts of the state that large quantities of young sprouts are removed from forests, leading to absence of new shoots and depletion of bamboo stock.

Bamboo culms are also used for preparing special dish of roasted meat. The hollow internode of big size Daba bamboo (Bambusa bamboos), with both the cross partitions intact, is used for this purpose. A hole is made in one of the cross partitions to stuff meat from one side. The meat is cut into small pieces, marinated with required quantity of oil, spices and condiments and kneaded for about 20 minutes for softening. The meat so prepared is then stuffed in side the lumen and the hole is closed with a small wooden peg. Two-centimeter thick clay is rubbed over the entire internode and then grilled over the radiating charcoal heat for about half an hour. When the clay becomes red hot the meat is supposed to be ready to be served. It is said that the taste of such roasted meat is excellent.

Bamboo shoot have high nutritional value and low fat, and are a good source of fibre.Bamboo shoots are rich in vitamins, cellulose and amino acids. At harvesting, a shoot may contain as much as 90% water. The edible content of a newly harvested shoot is typically around 30%; the balance is made up of the sheath, and the extreme portions of the shoot. Nutritional value is summarized as follows:

Most bamboo species produce edible shoots. In many parts of India, bamboo shoots have formed a part of traditional cuisine fresh, dried, shredded or pickled. There is however also a growing market for processed and packaged shoots, representing an opportunity for the establishment of commercially run processing units.

In India, there is as yet no significant cultivation for shoot nor is there an organised market or supply chain of raw shoots for processing. Plantations have however begun to be established, the preferred species for such plantations being Dendroclamus asper, Bambusa balcooa and Dendrocalmus hamiltonii. Organised cultivation for shoot requires a different package of practices from that for culm/ timber. Shoot cultivation normally requires better soil, water and light conditions, and more intensive management. A shoot stand consumes more mineral nutrients from the soil, and therefore the application of fertilisers, preferably organic fertilisers is important.

Growers cultivate bamboo shoots for home consumption, with the surplus finding its way to local markets. At present bamboo shoots are sold in India largely in unprocessed form - harvested from homestead clumps, and brought to local markets. Shelf life is limited, also since they tend to be harvested in the hot and humid season. Prices in urban markets for fresh shoots range from 5/- to 20/- per kg., but can be much higher in metro markets. Some quantities are sold dried and preserved with simple additives like salt and lemon juice. There is also a market for fermented shoots. On a slightly larger scale, slivered pickles are marketed. Modern processing and packaging technologies have developed new dimensions and markets for bamboo shoot. It is now possible, even at the scale of tiny and village level enterprise to prepare and pack shoots for the market, through processes that allow bamboo shoot to retain its freshness for a period of time. The NMBA is supporting the establishment of industrial scale processing units at Jorhat, Assam and Dimapur , Nagaland (www.nagalandfoods.com) These units have commenced production from the 2005 shoot season.

The Mission has also developed technology packages for bamboo shoot processing at the industrial scale, and for community/ village level enterprise. Using low cost equipment and simple processes, options for shelf life ranging from 9 days (in water) and 23 days (in brine) can be exercised to add value and provide additional income. such tiny scale enterprise can also function as part of a supply chain fom larger scale processing units. The community level technology package has been demonstrated by the NMBA at 24 locations, and has received an overwhelming response.

A study on edible bamboos conducted by Kerala Forest Research Institute (www.kfri.org) on six species namely, Bambusa bamboos, Bambusa tulda, Dendrocalamus brandisii, Dendrocalamus hamiltonii, Dendrocalamus longispathus, Dendrocalamus strictus, has shown that the shoot production season is from June-September. However, if regularly irrigated, the duration of emergence of new shoots can be increased. The shoots are harvested 7-14 days after the emergence when the shoot height will be about 15-30 cm depending upon the species. As per the figures obtained during studies carried out at KFRI, Peechi, Bambusa bamboos provided 23 shoots weighing 30-50 Kg. In Dendrocalamus hamiltonii, the average culm production was recorded to be 53 numbers weighing approximately 20-40 Kg.

It was found that the time for first harvest of shoots is about two and a half years after planting, if seedlings are used. In case of rooted node cuttings used as planting material the harvestable shoot is obtained with in two years.

The mean height of new shoots produced in different species is as shown below:

|

Years /1999-2002

|

|

Extractability of different species of bamboo

|

||||||||||||||||||||||||||||||

|

Given below is the bamboo shoot production/year recorded at Chessa bambusetum, Arunachal Pradesh (Data collected by the State Forest Research Institute, Itanagar) |

||||||||||||||||||||||||||||||

|

Average annual number of shoots per clump Period of shoot emergence

Other Products  |